Art Toys

Hand sculptured figurines with a mission

The artist Bine Lehmann, created the colorful female sculptures "U Go Grlz" with a mission to influence, challenge, and inspire to a different understanding of beauty. An understanding that accepts women and people as they are. U Go Grlz are a reminder, that if you are happy, you are beautiful.

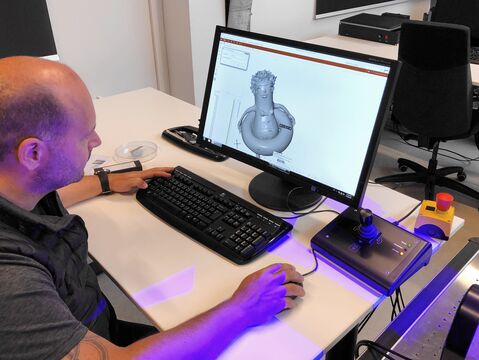

As a part of finding the best production method for U Go Grlz, Zebicon 3D scanned a series of the sculptures for Bine Lehmann. The project originated as a business way of thinking and the purpose was to reproduce and scale the art toys.

The most rewarding for me is to sculpture and paint the art toys. It is less inspiring to sculpture the same model twice. Furthermore, it will never be a true copy. – Bine Lehmann

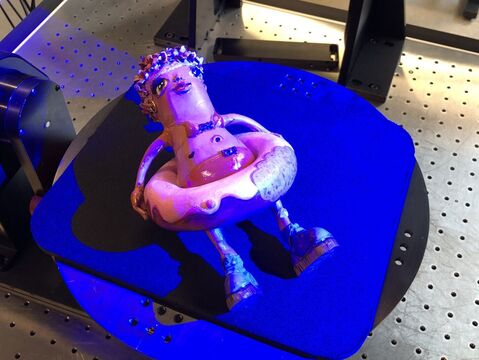

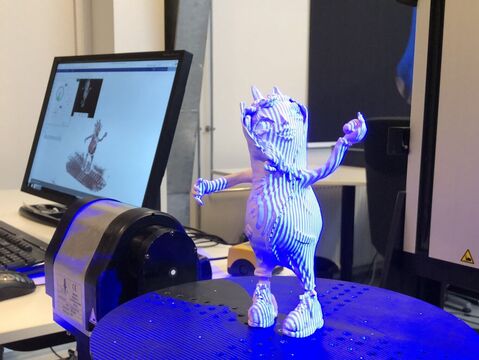

The first U Go Grlz were made in paper clay with many details, cavities and thin arms and fingers. Details which were digitized and documented by Zebicon’s high-end 3D scanner.

By working with 3D scanning and different methods of production, the artist Bine Lehmann learned a lot about her products.

The dream is to be able to 3D print the Art Toys. However, Bine Lehmann has realized, that the production costs for 3D print are too high currently. Therefore, she has adjusted the production.

I hope to get back to using 3D, as 3D scanning and printing are perfect for reproduction. – Bine Lehmann

Today, Bine Lehmann creates the original U Go Grlz in Polymer Clay, after which a silicone mold is made to hand cast the colorful female figurines.

Bine Lehmann has gotten several ideas to produce U Go Grlz, and has now found the ideal manufacturing process, where she sees great opportunities within the 3D technology.

I would rather go back to sculpting U Go Grlz in paper clay, as this is an incredible and manageable material to work with.

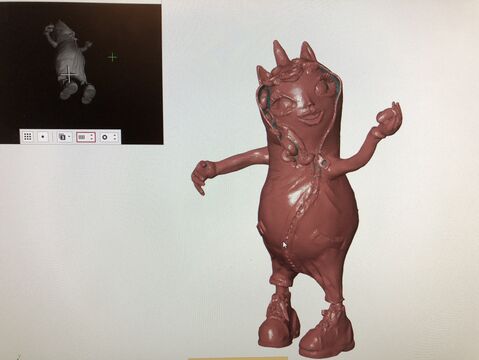

Afterwards, I would like to 3D scan the originals, so they can be scaled, modified, and used for different purposes such as Christmas ornaments, earrings, piggy banks, or large art toys. – Bine Lehmann

Bine Lehmann is planning to 3D print the modified versions and use them to create a mold for production.

3D scanning is a technology, which can create a digital 3D model of a physical part. The technology is primarily used for reverse engineering or quality control and part measurement.