ZEISS ScanBox Series 5

Production integrated quality control of complex geometries

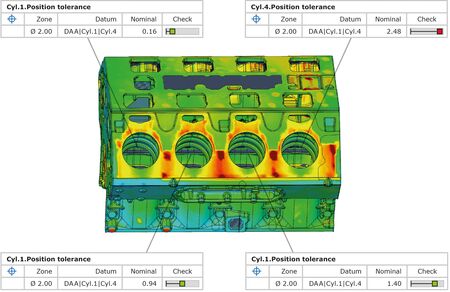

ZEISS ScanBox Series 5 is an all-in-one solution for automated quality control and digitization of complex parts. The powerful 3D scanner delivers complete measurement results for CAD comparison, which make any deviations visible.

The automated systems optimize batch inspection and help by checking the quality in manufacturing, repair, and maintenance.

Use the ZEISS ScanBox Series 5 to quickly define specific geometries and features such as surfaces, edges, and holes.

ZIESS ScanBox 5110

ZEISS ScanBox 5120

ZEISS Scanbox 5130

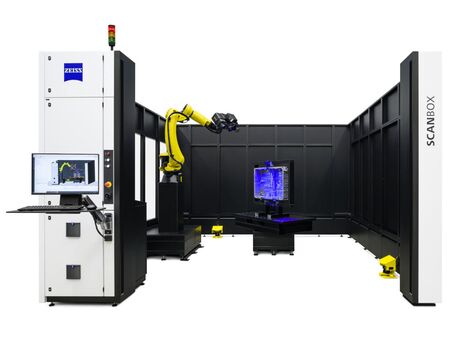

ZEISS ScanBox Series 5 consists of three versions, which are built around the same principle. All versions use an ATOS scanner on a 6 axis robot in combination with a rotation table.

The system can measure a large range of part sizes, which allow you to choose the system that suits your needs. All versions can handle items up to 2 tons.

The ZEISS ScanBox 5110 is suitable for measurement and inspection of complex parts, such as turbine blades and metal castings up to 1000 mm.

The ZEISS ScanBox 5120 is more spacious, which makes it suitable for measuremnet of larger parts, such as car doors, engine blocks etc. up to 2000 mm.

The ZEISS ScanBox 5130 can measure parts up to 3000 mm, which makes it ideal for quality control of castings, sheet metal parts, and larger turbine components.

The scanned data allows you to analyze individual parts or part series and perform complete part verification. It gives you greater understanding of the part's characteristics, and trends in a production.

The automatic solution saves time by serial measurements and by recurring parts, and ensures the same standard of each measurement.

The new flexible user interface has various ergonomic features to support the user. The computer is places at the front of the machine, where the screen is mounted on an arm. This makes it possible to operate the equipment in both standing and seated position.

| ZEISS ScanBox 5110 | ZEISS ScanBox 5120 | ZEISS ScanBox 5130 | |

|---|---|---|---|

| Dimensions | 2200 × 3550 × 3050 mm (LC*) | 3600 × 4250 × 3050 mm (LC) | 4300 x 4250 x 3050 mm (LC) |

| 2200 x 2850 x 3050 mm (D**) | 3600 x 3550 x 3050 mm (D) | ||

| Power supply | 200-500 V (3-phases, 16 A) | 200-500 V (3-phases, 16 A) | 200-500 V (3-phases, 16 A) |

| Max. part size | Ø1000 mm | Ø2000 mm | Ø3000 mm |

| Max. part weight | Up to 2000 kg | Up to 2000 kg | Up to 2000 kg |

| Automated axes | 7 | 7 | 7 |

| Entry | Light sensor, sliding door with safety lock | Light sensor, sliding door with safety lock | Light sensor |

| Opening width | 1000 mm (LC) | 2400 mm (LC) | 3100 mm (LC) |

| 950 (D) | 2100 mm (D) | ||

| Floor mounting | Yes | Yes | Yes |

| Loading concept | Manual, crane | Manual, crane, truck | Manual, crane, truck |

| Sensor compatibility | ATOS 5 Airfoil | ATOS 5, ATOS 5 Airfoil | ATOS 5 |

*LC: Light curtain

**D: Door

ATOS 5 is a high-end 3D scanner with a strong LED light source, which ensures high data accuracy for a variety of applications. Available for both manual and automated setup.

ATOS Plus is an add-on to the ATOS scanners, and is a combination of 3D scanning and photogrammetry. Using ATOS Plus a completely automated measurement process is obtained.