3D scanning

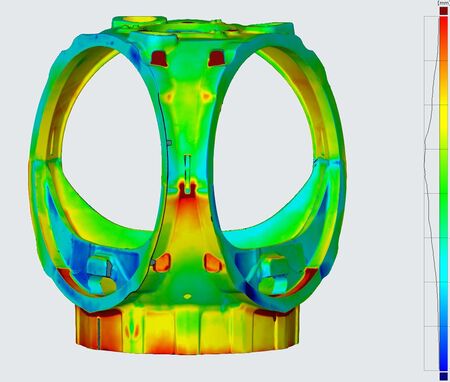

3D scanning is a technology, which can create a digital 3D model of a physical part. The technology is primarily used for reverse engineering or quality control and part measurement.

At Zebicon we are specialists in 3D scanning and industrial measuring techniques. We offer services within 3D scanning and measuring and sell optical metrology systems from the German company GOM.

With state-of-the-art equipment and great know-how technically and professionally, we can assist you in both simple and complex measurements.

At Zebicon we offer to be your discussion partner within metrology and 3D measurement. We work in many industries and use this knowledge to enhance and develop new solutions across industries.

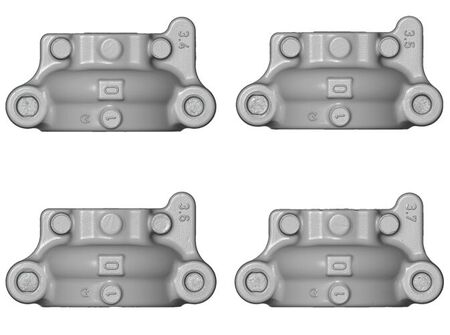

Zebicon offers services within 3D part verification of all types of part, tool or component.

A 3D measurement can be done using different technologies. Either a 3D scanning, which results in a full-field surface measurement, or a CT scanning, which documents both internal and external geometries. Another possibility is a 3D coordinate measurement, where only selected points are measured.

3D part verification can be used for:

Zebicon offers services within reverse engineering on all types of parts from design objects, art, and industrial components. Depending on the size and mobility of the part, the measurement is either conducted in Zebicon's laboratory or by the customer on-site.

3D scanning for reverse engineering is a shortcut in the development process, as you receive a complete digital 3D model of your part in a very short time. In addition to forming the basis for CAD design, the scanned data can be scaled, copied, and inverted.

Reverse engineering can be used for:

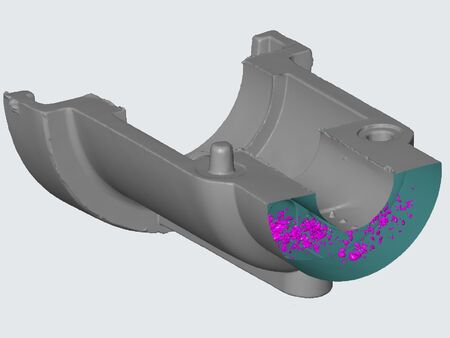

Zebicon offers material analysis of small parts for inspection and documentation of fiber structure, air inclusions, and internal defects. This type of analysis is done with CT scanning, also called Computer Tomography.

CT scanning is x-ray technology, which means that both inner and outer geometry is documented and material details can be analyzed.

Material analysis can be used for:

Zebicon offers analysis of electronics and assembled parts to document interaction between elements, solderings, integrated circuits, short circuits etc. The analysis is typically used for confirming or disconfirming source of errors, and for checking if components are located appropriately after assembly.

This type of analysis is conducted using CT scanning. The process is non-destructive, hence, it is possible to document details without destroying or dismantling the part.

Component analysis can be used for:

Technical Director

+45 41 96 49 53

ksd@zebicon.com

Do you have parts that need to be measured? Send a request with a short description of your measurement job. Please attach a photo or a technical drawing of you part.

3D scanning is a technology, which can create a digital 3D model of a physical part. The technology is primarily used for reverse engineering or quality control and part measurement.

CT scanning is x-ray scanning in 3D and is also called computer tomography. The technology is ideal for part measurement and material analysis, as both internal and external geometries are documented.

Photogrammetry is optical 3D coordinate measurement. The technology is used for quality control of large parts, verification of fixtures and hand held tools as well as static deformation analysis.