Handmade performance tuning is copied

Zebicon scans the cylinder head from Kenneth Bjerre's speedway bike to create an exact copy

Bjerre Racing is the team behind the two young succesful speedway riders Kenneth og Lasse Bjerre. The team experienced that enginees of the same make and with identical technical specifications did not perform identically, and that one engine outperformed the others.

The reason for the difference is to be found in the way the cylinder head is manufactured. The process consists of automated milling, followed by manual working with a grinding machine. The result of the manual grinding is that two cylinder heads never become 100% identical, and consequently the rider prefers one engine over another.

Problem

Bjerre Racing wanted an exact copy of the preferred cylinder head to be able to mill a new cylinder head with the same dimensions. This way, they would have two speedway bikes performing identically.

Solution

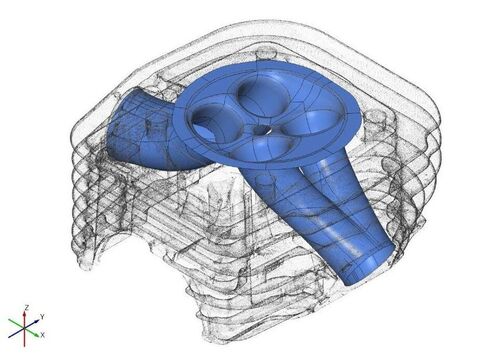

Zebicon 3D scanned the cylinder head and delivered the surface geometry of the hand grinded inlet ports. The result of the scanning, an IGES surface file, was delivered to the tool factory Værktøjsfabrikken Paw, who used the scanned data to create a CAM program for milling a new cylinder head with identical dimensions. This way, an exact copy of the original cylinder head was created.

"Previously it has not been possible to obtain the same test result for two engines," explains manager Ivan Bjerre. "Now we succeeded in doing it, as it works really well. Everything runs more smoothly, and it is significantly better than what we have been used to with other new cylinder heads."

With the new custom-made cylinder head Kenneth Bjerre no longer has preferences as to which engine he uses for races.

3D scanning is a technology, which can create a digital 3D model of a physical part. The technology is primarily used for reverse engineering or quality control and part measurement.