FoodTech fair gets a taste of 3D scanning

FoodTech fair gets a taste of 3D scanning

We are ready to test new markets and participates at the FoodTech fair in Herning for the first time.

3D scanning and geometric metrology normally found its usage outside the food industry. But a rising demand in part verification, quality control and optimization in the food industry has paved the road for Zebicon. Therefore we have decided to attend this years FoodTech fair for the first time.

From cans to chickens

The 3D scanning technology is already widely used in plastic and metal industries for verification of parts. A part can after it has been scanned, be compared to its CAD equivalent, and any deviations between the constructed and the produced part is visualized with colors. In the food industry, manufacturers of cans and plastic containers use the color comparison to quickly get an overview of the general trends and quality in their production.

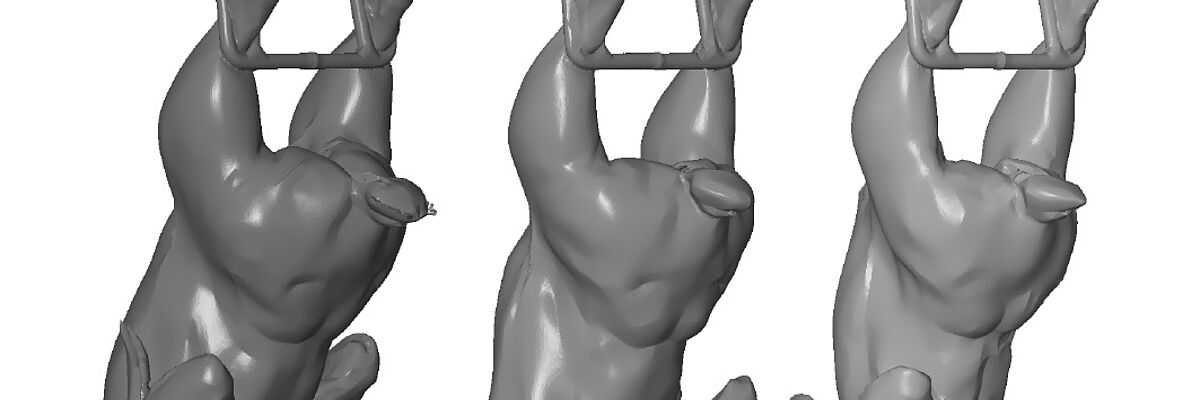

The technology finds a wide variety of uses in the food industry. An example is the digitization of chickens in a suspension. They were used in a programming and production simulation. The scan led the customer to make the necessary adjustments before a costly production was initiated.

3D scanning can also be used in process optimization, which is an important part of many Danish industries. The accuracy of 3D technology means that even small scuff marks and stress points on cutting knives and tools can be documented. This allows companies to make tool changes based on valid data.

Meet us when we are attending FoodTech for the first time in MCH

We are located at M 9864 ready to demonstrate the 3D scanning technology. here you will be able to talk to us about 3D scanning and metrology, and how your company may benefit from this technology.