Memorial stone on Langelinie captured with 3D scanning

3D scanning of cultural heritage

At Langelinie you will find the memorial stone to Ludvig Mylius Erichsen, N.P. Høgh Hagen and Jørgen Brønlund, who all died on the Danish expedition in Greenland in 1907.

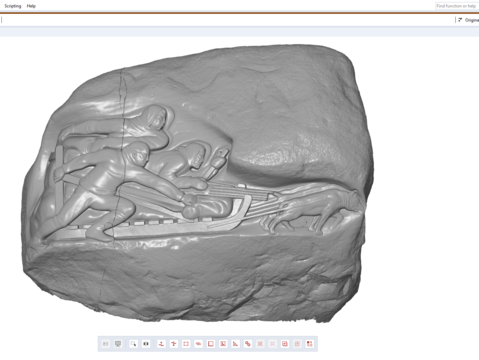

The memorial stone shows the three expedition participants pushing their sledge to relieve the dogs pulling the sledge.

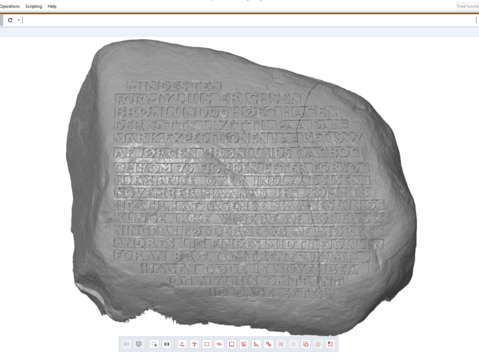

The memorial stone is carved from the rock type Scanian basalt, which has some internal structures causing weaknesses. Weaknesses that, according to Susanne Trudsø, Conservator at the National Museum, were hardly recognized in 1911 when Kai Nielsen carved the stone and made it into a monument.

The internal structures caused the monument to start cracking as early as the 1930s. Later, the crack developed, and the first securing was carried out. However, the cracks continued to develop, and the stone cracked, so in the 1970s it had to be further secured.

Zebicon has 3D scanned the memorial stone, which measures 3.9 x 3.9 x 2 meters, creating a digital twin of the monument. The scan is a documentation of the here-and-now situation.

"The question today is whether the protection is dimensioned strongly enough in relation to the weight of the monument and whether further measures are needed. We suspect that the crack has developed slightly since the 1970s, but we don't have a scan from that time for comparison." - Susanne Trudsø, Conservator at the National Museum of Denmark

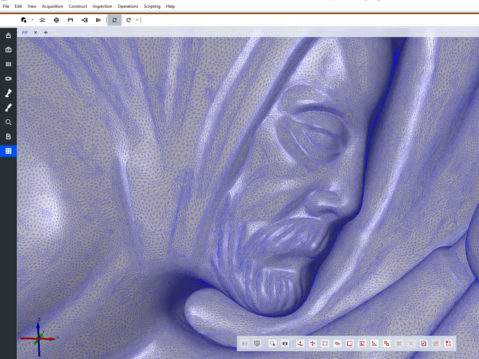

The memorial stone was 3D scanned with the handheld scanner ZEISS T-SCAN hawk 2. In order to maintain a high level of precision in the scan, reference marks were applied to the stone to connect the different scans correctly.

The task was completed in a total of 6-7 hours, of which 3-4 hours were spent scanning and the remaining time preparing and removing the marks.

The 3D scanning provides a great representation of what you can see and experience when you visit the memorial. It documents the course of the crack and the precise geometry of the crack opening, which can be used for comparison and analysis of the development in the coming years.

''Now there is a scan, and in 5-10 years it will be possible to make a new scan and then compare the two scans.” - Susanne Trudsø, Conservator

In addition to documenting the existing cracks, the 3D scanning resulted in a detailed surface model of the monument, showing great detail of both the text on one side and the figures on the other.

This provides a reference model that can be used to document the overall condition of the memorial and determine whether further micro-cracks are developing, which over time can develop into larger cracks.

3D scanning is a technology, which can create a digital 3D model of a physical part. The technology is primarily used for reverse engineering or quality control and part measurement.