Plugs

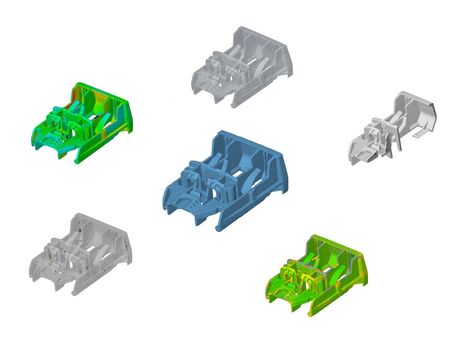

Belden Cekan A/S uses CT scanning to document and validate parts in the development department, where they look at geometries, positioning and contact elements.

CT scanning is x-ray scanning in 3D also called computer tomography. The technology is ideal for part verification and material analysis, as both inner and outer dimensions are documented.

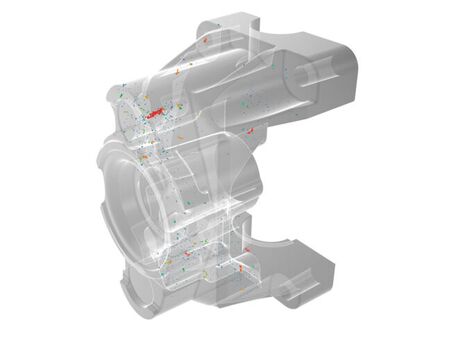

With CT scanning it is possible to inspect cavities, channels, and other hidden details as well as analyze interactions between mounted parts.

3D computer tomography works by placing a part in front of an x-ray source which rotates 360º.

While the part is rotating, cross-sectional x-ray images are captured on a detector panel, and by using advanced software, the images are combined into a 3D model.

CT scanning is primarily used for quality control and part verification, material analysis, and analysis of electric components and assembled parts.

At Zebicon we offer services within CT scanning of smaller parts up to Ø200 mm. Furthermore, we are distributor of the CT scanner series ZEISS METROTOM.

Belden Cekan A/S uses CT scanning to document and validate parts in the development department, where they look at geometries, positioning and contact elements.

Oticon A/S wanted to check the quality of the component 'hook'. Zebicon used CT scanning to make a full-field surface documentation and measure the inner geometries.

GN Netcom wanted more knowledge about the interaction between internal elements in an assembled headset, including location and connection between cables, PCB, and speaker.

With a ZEISS METROTOM computer tomograph all dimensions can be measured and inspected with a single scan. Additionally, it is possible to measure multiple components simultaneously in the CT scanner, depending on the size of the parts.

Furthermore, extra dimensions can be inspected at any given time by using the generated data to do additional analysis. By comparing the scanned data to CAD data, a color plot is made. This gives a visual overview of the part’s dimensional precision.

The particular strength of the ZEISS METROTOM is, that the measuring results are traceable and meet the current metrology standards.

The ZEISS METROTOM series offer a broad variety of CT scanners. You can find systems with great usability and small footprint, as well as advanced CT scanners for the most demanding measurements.

With more than 10 years on the market, the METROTOM systems are based on a well proved technology, and is a measurement method acknowledged by the industry.

All METROTOM CT scanners are delivered with ZEISS INSPECT. This software is a powerful tool, which provides many opportunities for the following inspection and analysis.

ZEISS METROTOM 1

ZEISS METROTOM 1 is a small and user-friendly CT scanner for measurement of plastic parts and parts of light metal. It is applicable for parts up to Ø170 mm and H 150 mm.

ZEISS METROTOM 800 130 kV

ZEISS METROTOM 800 130 kV is suitable for measurement of plastic parts with high precision. It is applicable for parts up to Ø300 mm and H 260 mm.

ZEISS METROTOM 6 scout

ZEISS METROTOM 6 scout has ultra-high resolution and is suitable for scanning of plastic parts up to Ø200 mm and H 400 mm.

ZEISS METROTOM 800 225 kV

ZEISS METROTOM 800 225 kV is suitable for quick measurement of parts produced of a more compact material. It can measure parts up to Ø300 mm and H 360 mm.

ZEISS METROTOM 1500

ZEISS METROTOM 1500 is suitable for quick scanning of large and heavy parts up to Ø615 mm, H 800 mm and 50 kg.

| METROTOM 1 | METROTOM 800 130 kV | METROTOM 6 scout | METROTOM 800 225 kV | METROTOM 1500 | |

|---|---|---|---|---|---|

| Dimensions (mm) | 1750 x 1820 x 870 | 1960 x 2190 x 1310 | 2130 x 2200 x 1230 | 2050 x 3200 x 1820 | 2440 x 3700 x 1810 |

| Weight (kg) | 2100 | 5700 | 4800 | 5000 | 6600 |

| Automated axes | 1 | 3 | 5 | 3 | 3 |

| X-ray source (kV) | 160 | 130 | 225 | 225 | 225 |

| Detector panel (pix) | 2560 x 2560 | 1536 x 1920 | 3008 x 2514 | 1024 x 1024 | 3072 x 3072 |

| Min. focal spot (mm) | - | 0.005 | 0.004 | 0.007 | 0.007 |

| Temperature control | Yes | Yes | Yes | Yes | Yes |

| Part size (mm) | Ø170, H 150 | Ø300, H 360 | Ø240, H 400 | Ø300, H 390 | Ø616, H 800 |

| Part weight (kg) | 5 | 5 | 5 | 5 | 50 |

At Zebicon we do CT scanning as a measurement service. Get your parts measured for a fixed low price or get a quotation for your measurement task. We offer technical consult and CT scanning of the highest quality.

ZEISS INSPECT X-ray is a software for analysis and visualization of CT data. The software is ideal for analysis of inner geometries, and gives you alle the known inspection possibilities such as, alignment, GD&T, and comparison to CAD.